-

TEL

+86 (0)631 570 2800

Zip:264207

Add:No.30 jinshan Road, Chucun Town, Hi-tech Industrial Development Zone,Weihai,Shandong Province

Manual

1위 해 연 화 안 전 유 리 유 한 회 사

자동자안전유리마크、운반、포장、보관、조립、사용、폐기설명

1 적용범위

당사생산한자동자안전유리의마크、운반、포장、보관、조립、사용、폐기과정 적용합니다

2 인용표준

GB9656-2003《자동자용 안전유리》

JC/T512-93《자동차 안전유리 포장》

GB191《포장운반표시》

KSL2007《자동자용 안전유리》

3 마크、운반、포장、보관 기술요구

3.1 제품

a.제품검사후GB9656-2003《자동자용안전유리》、KSL2007《자동자용안전유리》의표준요구 만족이나 고객님 특수요구 만족,검사원 검사합격후 포장진행함;

b.제품마크(예CCC、상표)선명도및영구성보증。YH3-2-51《연화회사자동자안전유리영구성마크사용설명》。

3.2 포장

3.2.1 포장자재

a. 포장box:포장box 운반시 안전 및 제품품질 보증함

b. 방습종이:유리사이、유리과포장box사이 방습종이추가로 유리 기스 방지;

c. 기타 자재 고객님 요구따라 변경진행。

3.2.2 포장

a.안전유리 포장시 동향입식로 포장. 유리사이 방습종이로 사용함

b.보호장치필요시 box밑에 고무판사용。고무판고정시 스크루 고무밑에5mm이하 고정 ;유리과 box 사이 쿠션사용으로 운반시 유리 흔들림 방지。

c.포장후 무게500Kg 초과 안됨(고객님 요구따라 변경진행)

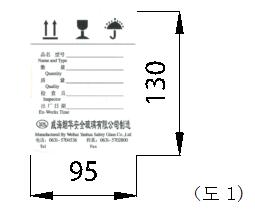

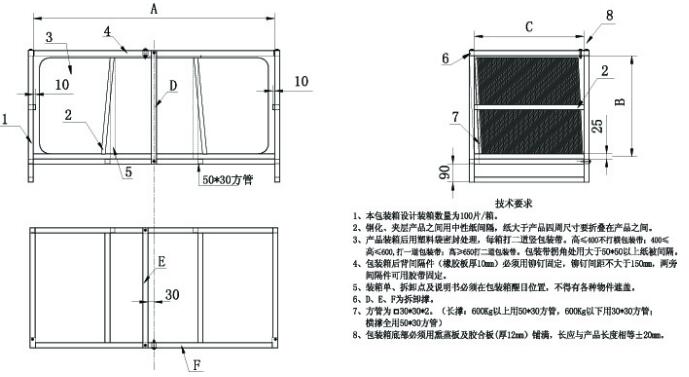

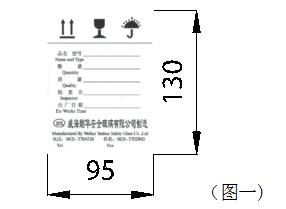

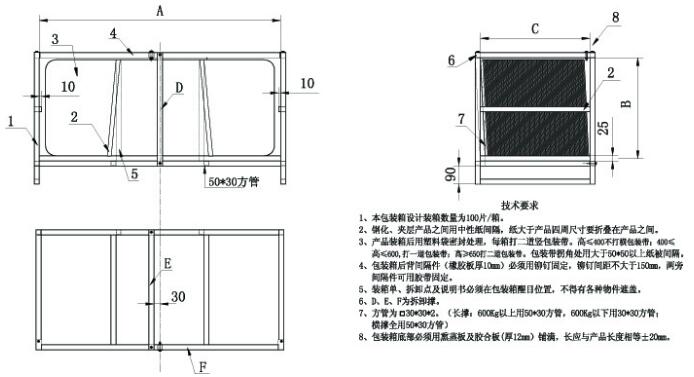

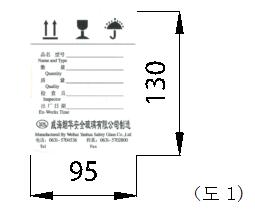

d.보통 box표시내용:모델、수량、품질、검사원、제조일정등(도1)

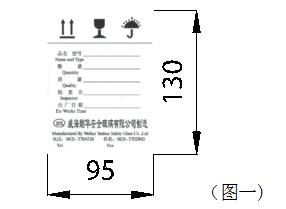

e.고객님특수요구시,변경진행.예:한국제품 box표시내용:모델、두께、유리종류(도2) KS마크“ ”직경12mm。

”직경12mm。

3.2.3 포장표시

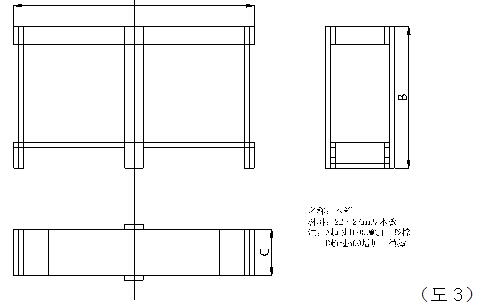

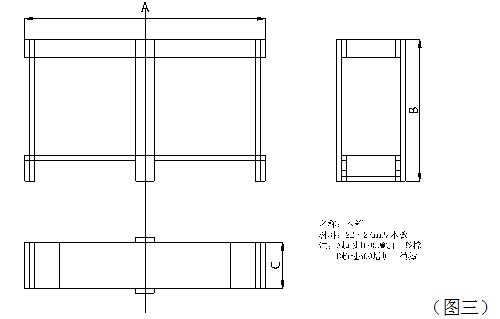

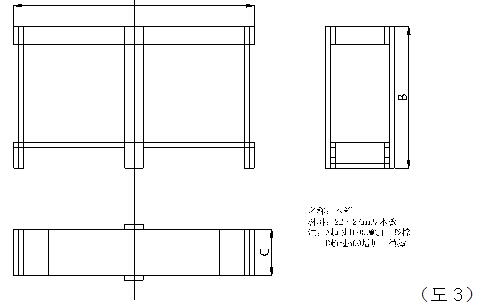

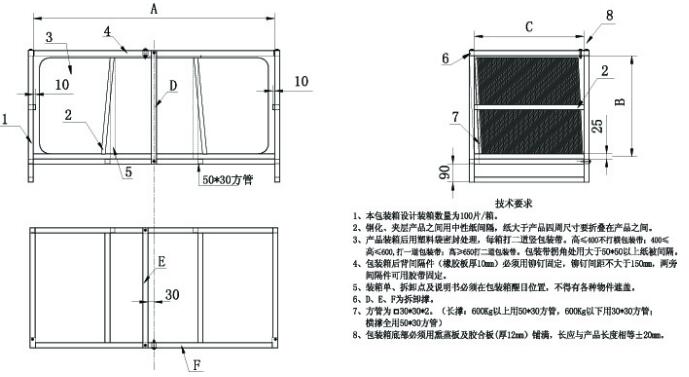

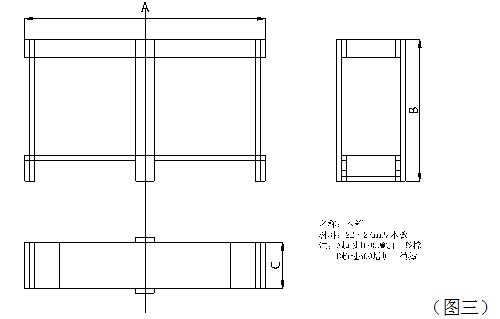

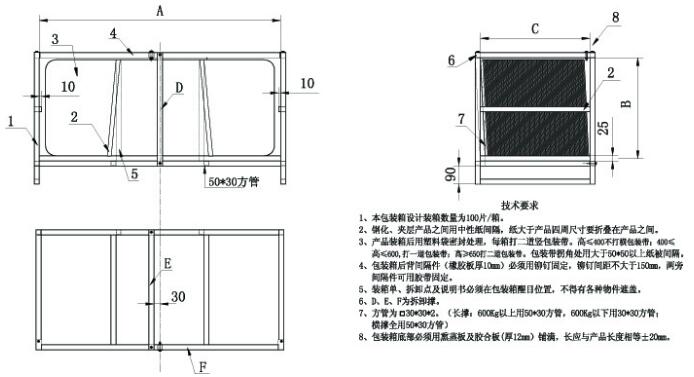

a.제품 포장box외 표시(도1),포장box구성도(도3)

b.고객님 특수요구시 제작진행。도2(한국제품):포장box 잘 보이는쪽부착 (도2),표시내용:KS미크、한국산업표준(KS)이나 한국산업표준(KS)코드번호、인증번호、제조일자、제조자명、인증기관명、KSL2007마크사항。포장box구성도(도4)

3.3 보관

a. “향상”표시로 보관;

b. 제품별 분류보관 진행;

c. 입고시간별로 보관,“선입선출”;

d. 정기검사로 제품 보관상테 및 출고서류 확인;

e.통풍 건조한 실내에서 보관진행。

3.4 운반

3.4.1 운송방식

자동차로운송,기타운송방식 서로상의진행。

3.4.2 운송보호

a. 방우설비 ;

b. 운송과정중 box“향상”표시로방치;

c. 운송시 유리 길이방향 과 차량 운행방향 일치,무너진방치 보증。

4조립 및 조립방법 설명서

4.1 조립방법

1) 운송과정중 불량발생 방지위해 생산완료한 제품 box이나 대차로 고객님 요구한포장방식 포장후 운송진행。

2) 조립시 유리파손방지

3)조립시 작업자 보호복 작용으로 유리파손 다침방지。

4)고정시 고무망치사용으로 유리파손 방지。

5)기타사항 협상진행。

4.2 조립시 주의사항

1) 납품후 고객님 검사、확인후 조립진행.

2) 포장 회수필요시 보관진행;폐기물 환경오염방지。

3제품 조립전 청결 전조 통풍한 창고에서 보관진행.습기 충격 방지。

5사용주의사항

1)고온환경에서 냉수로 세척금지 (파손가능)

2)겨울에 온수로 세척금지(온도차이로 유리파손가능)

3)FRONT GLASS 세척시 지정한 세척재사용으로 유리보호;유리 표면 눈、결빙등 장애물 발생시 wier 사용금지。

6 유리의 폐기처리

1)자동차유리 순환사용 불가능으로 회수후 각종유리병이나 기타유리제품 재사용 진행。현재 자동자 고강도 접합유리사용하고 있음。접합유리는 보통유리 사이에 필름추가로 유리안전성 및 강화증가함。접합유리 회수후 가열로 유리과 필름 따로 분리회수진행。

2)회수 불가시 환경보호 요구대로 폐기처리진행(환경오염방지)。

Weihai Yanhua Safety Glass Co., LTD

Automobile safety glass labeling, handling, packaging, storage, installation, use, scrap instructions

1 Scope of application

This instruction applies to the process of marking, handling, packaging, storage, installation, use and scrapping of safety glass for automobiles produced by our company

2 Reference Standards

Gb9656-2003 safety Glass for Automobile

JC/T512-93 Automobile Safety Glass Packaging

GB191 "Packaging, Storage and Transportation Pictorial Signs"

KSL2007 "Safety Glass for Automobiles"

Technical requirements for identification, handling, packaging and storage

3.1 products

A. After inspection, the product meets the requirements of GB9656-2003 "Safety Glass for Automobile" and KSL2007 "Safety Glass for Automobile"; Or has met the customer's special requirements, the inspection personnel inspection can be packaged;

B. Product marks (such as CCC and trademark) shall be permanent, non-bruising, traceable, clear, easy to read and remember. See YH3-2-51 "Instructions for use of Automobile Safety Glass Permanent Label of Yanhua Company".

3.2 the packing

3.2.1 Packaging Materials

A. Packing case: the materials used in the packing case shall be strong enough to facilitate loading, unloading and shoveling and ensure that the product quality will not be affected during normal storage and transportation.

B. Lining paper: Lining paper or other light and soft materials shall be used as spacers or fillers between each piece of glass and between glass and packing case to prevent damage to glass;

C. Other auxiliary materials can be determined according to customer requirements.

3.2.2 packing

A. Safety glass should be packed in the same direction and placed vertically. Each piece of glass should be close together and lined with lining paper

B. Protective measures, if necessary, the bottom of the box should have soft padding, such as rubber and plastic board, etc. The nail fixing the liner should be 5mm or so lower than the liner or glued to the bottom of the case with adhesive; Foamed board should be used between the glass and the packing case to prevent the glass from moving during handling or transportation.

C. The total weight of the packed parts shall not exceed 500Kg (if the customer has other requirements, it will be handled separately)

D. General packing list includes: product name, model, quantity, quality, inspector, date of delivery, as shown in Figure 1:

E. If customers have special requirements, it will be handled separately. For example, the packing list of products exported to South Korea includes product name, nominal thickness and type of glass. Figure 2: The diameter of the KS certification mark is 12mm.

3.2.3 Packaging label

A. There should be eye-catching and indelible marks on the outer surface of the product packing box as shown in Figure 1, and the structure of the packing box as shown in Figure 3.

B. Special requirements of customers will be handled separately. Figure 2 (Korean products) : there should be inscrutable marks on conspicuous places in product packing boxes, as shown in Figure 2, including KS mark, Korean Industrial Standard (KS) name or Korean Industrial Standard (KS) number, certification number, manufacturing year, month and date, manufacturer name or abbreviation, certification authority name, KSL2007 logo. See Figure 4 for the structure of the packing case

3.3 the storage

A. The container must be placed strictly according to the "up" mark;

B. Different products should be stored in accordance with the content card, in order to avoid mixing and mispayment;

C. Store according to storage time to facilitate "first-in, first-out";

D. Inspect and evaluate the storage status of products from time to time, and complete the procedures in and out of storage;

E. The packing case should be stored in a dry and ventilated room or shed, and the bottom of the packing case should be raised when necessary.

3.4 handling

3.4.1 Mode of transport

By road transportation, other modes of transportation to be agreed by both parties.

3.4.2 Transportation Protection

A. Rain protection facilities shall be provided;

B. During transportation, the packing boxes should be placed according to the "up" mark, not flat or inclined;

C. During transportation, the length of the glass boxes should be in the same direction as that of the vehicle. The boxes should be close together, and measures should be taken to prevent tipping.

Instruction of assembly and construction method

4.1 Installation Method

1) In order to prevent damage during transportation, the produced products shall be packed in boxes, racks or in the form of packaging required by the customer and sent to the place agreed upon by both parties.

2) The installation process should be handled with care to prevent glass breakage.

3) During installation, installation personnel should use protective equipment to prevent glass from breaking and wounding.

4) When installing, use a soft rubber hammer to tap the installation part to prevent the glass from breaking.

5) Other matters not mentioned are subject to the agreement between the parties.

4.2 Precautions during Installation

1) The delivered products shall be checked and confirmed by the customer before installation.

2) When the packaging needs to be recycled, it needs to be properly preserved; Waste prevents pollution of the environment.

3) The delivered products should be stored in a clean, dry and ventilated warehouse before installation to prevent dampness, rain or heavy impact.

5 Precautions for Use

1) It is not recommended to clean the glass with cold water immediately after high temperature exposure to prevent glass breakage

2) In winter defrost, do not use hot water to clean the glass, to prevent the temperature difference ambassador glass broken

3) Clean the front windshield, try to use the specified window cleaner. Because the cleaning liquid added to dissolve oil, improve the glass wetting interface components, conducive to the maintenance of glass; When there is snow, ice, mud blocks, dry bird droppings and other obstacles on the glass, do not use the wiper, otherwise it will cause damage to the wiper blade, wiper motor and glass damage.

6. Scrap treatment of glass

1) The technical performance of automotive glass manufacturing secondary products is lower than that of primary products, so they are mainly used to manufacture all kinds of glass bottles or other glass products. Automotive glass in addition to the traditional glass, is now widely used in order to improve the strength of the sandwich glass. The so-called laminated glass is sandwiched between two layers of ordinary glass with a high molecular polymer layer to increase the safety of the glass. This glass recovery allows the laminated glass to be heated to the softening temperature of the intermediate polymer, thus separating the glass and polymer and recycling them separately.

2) If it cannot be recycled, please classify the waste glass and discard it in the trash bin in accordance with environmental protection requirements to avoid environmental pollution.

자동자안전유리마크、운반、포장、보관、조립、사용、폐기설명

1 적용범위

당사생산한자동자안전유리의마크、운반、포장、보관、조립、사용、폐기과정 적용합니다

2 인용표준

GB9656-2003《자동자용 안전유리》

JC/T512-93《자동차 안전유리 포장》

GB191《포장운반표시》

KSL2007《자동자용 안전유리》

3 마크、운반、포장、보관 기술요구

3.1 제품

a.제품검사후GB9656-2003《자동자용안전유리》、KSL2007《자동자용안전유리》의표준요구 만족이나 고객님 특수요구 만족,검사원 검사합격후 포장진행함;

b.제품마크(예CCC、상표)선명도및영구성보증。YH3-2-51《연화회사자동자안전유리영구성마크사용설명》。

3.2 포장

3.2.1 포장자재

a. 포장box:포장box 운반시 안전 및 제품품질 보증함

b. 방습종이:유리사이、유리과포장box사이 방습종이추가로 유리 기스 방지;

c. 기타 자재 고객님 요구따라 변경진행。

3.2.2 포장

a.안전유리 포장시 동향입식로 포장. 유리사이 방습종이로 사용함

b.보호장치필요시 box밑에 고무판사용。고무판고정시 스크루 고무밑에5mm이하 고정 ;유리과 box 사이 쿠션사용으로 운반시 유리 흔들림 방지。

c.포장후 무게500Kg 초과 안됨(고객님 요구따라 변경진행)

d.보통 box표시내용:모델、수량、품질、검사원、제조일정등(도1)

e.고객님특수요구시,변경진행.예:한국제품 box표시내용:모델、두께、유리종류(도2) KS마크“

3.2.3 포장표시

a.제품 포장box외 표시(도1),포장box구성도(도3)

b.고객님 특수요구시 제작진행。도2(한국제품):포장box 잘 보이는쪽부착 (도2),표시내용:KS미크、한국산업표준(KS)이나 한국산업표준(KS)코드번호、인증번호、제조일자、제조자명、인증기관명、KSL2007마크사항。포장box구성도(도4)

3.3 보관

a. “향상”표시로 보관;

b. 제품별 분류보관 진행;

c. 입고시간별로 보관,“선입선출”;

d. 정기검사로 제품 보관상테 및 출고서류 확인;

e.통풍 건조한 실내에서 보관진행。

3.4 운반

3.4.1 운송방식

자동차로운송,기타운송방식 서로상의진행。

3.4.2 운송보호

a. 방우설비 ;

b. 운송과정중 box“향상”표시로방치;

c. 운송시 유리 길이방향 과 차량 운행방향 일치,무너진방치 보증。

4조립 및 조립방법 설명서

4.1 조립방법

1) 운송과정중 불량발생 방지위해 생산완료한 제품 box이나 대차로 고객님 요구한포장방식 포장후 운송진행。

2) 조립시 유리파손방지

3)조립시 작업자 보호복 작용으로 유리파손 다침방지。

4)고정시 고무망치사용으로 유리파손 방지。

5)기타사항 협상진행。

4.2 조립시 주의사항

1) 납품후 고객님 검사、확인후 조립진행.

2) 포장 회수필요시 보관진행;폐기물 환경오염방지。

3제품 조립전 청결 전조 통풍한 창고에서 보관진행.습기 충격 방지。

5사용주의사항

1)고온환경에서 냉수로 세척금지 (파손가능)

2)겨울에 온수로 세척금지(온도차이로 유리파손가능)

3)FRONT GLASS 세척시 지정한 세척재사용으로 유리보호;유리 표면 눈、결빙등 장애물 발생시 wier 사용금지。

6 유리의 폐기처리

1)자동차유리 순환사용 불가능으로 회수후 각종유리병이나 기타유리제품 재사용 진행。현재 자동자 고강도 접합유리사용하고 있음。접합유리는 보통유리 사이에 필름추가로 유리안전성 및 강화증가함。접합유리 회수후 가열로 유리과 필름 따로 분리회수진행。

2)회수 불가시 환경보호 요구대로 폐기처리진행(환경오염방지)。

Weihai Yanhua Safety Glass Co., LTD

Automobile safety glass labeling, handling, packaging, storage, installation, use, scrap instructions

1 Scope of application

This instruction applies to the process of marking, handling, packaging, storage, installation, use and scrapping of safety glass for automobiles produced by our company

2 Reference Standards

Gb9656-2003 safety Glass for Automobile

JC/T512-93 Automobile Safety Glass Packaging

GB191 "Packaging, Storage and Transportation Pictorial Signs"

KSL2007 "Safety Glass for Automobiles"

Technical requirements for identification, handling, packaging and storage

3.1 products

A. After inspection, the product meets the requirements of GB9656-2003 "Safety Glass for Automobile" and KSL2007 "Safety Glass for Automobile"; Or has met the customer's special requirements, the inspection personnel inspection can be packaged;

B. Product marks (such as CCC and trademark) shall be permanent, non-bruising, traceable, clear, easy to read and remember. See YH3-2-51 "Instructions for use of Automobile Safety Glass Permanent Label of Yanhua Company".

3.2 the packing

3.2.1 Packaging Materials

A. Packing case: the materials used in the packing case shall be strong enough to facilitate loading, unloading and shoveling and ensure that the product quality will not be affected during normal storage and transportation.

B. Lining paper: Lining paper or other light and soft materials shall be used as spacers or fillers between each piece of glass and between glass and packing case to prevent damage to glass;

C. Other auxiliary materials can be determined according to customer requirements.

3.2.2 packing

A. Safety glass should be packed in the same direction and placed vertically. Each piece of glass should be close together and lined with lining paper

B. Protective measures, if necessary, the bottom of the box should have soft padding, such as rubber and plastic board, etc. The nail fixing the liner should be 5mm or so lower than the liner or glued to the bottom of the case with adhesive; Foamed board should be used between the glass and the packing case to prevent the glass from moving during handling or transportation.

C. The total weight of the packed parts shall not exceed 500Kg (if the customer has other requirements, it will be handled separately)

D. General packing list includes: product name, model, quantity, quality, inspector, date of delivery, as shown in Figure 1:

E. If customers have special requirements, it will be handled separately. For example, the packing list of products exported to South Korea includes product name, nominal thickness and type of glass. Figure 2: The diameter of the KS certification mark is 12mm.

3.2.3 Packaging label

A. There should be eye-catching and indelible marks on the outer surface of the product packing box as shown in Figure 1, and the structure of the packing box as shown in Figure 3.

B. Special requirements of customers will be handled separately. Figure 2 (Korean products) : there should be inscrutable marks on conspicuous places in product packing boxes, as shown in Figure 2, including KS mark, Korean Industrial Standard (KS) name or Korean Industrial Standard (KS) number, certification number, manufacturing year, month and date, manufacturer name or abbreviation, certification authority name, KSL2007 logo. See Figure 4 for the structure of the packing case

3.3 the storage

A. The container must be placed strictly according to the "up" mark;

B. Different products should be stored in accordance with the content card, in order to avoid mixing and mispayment;

C. Store according to storage time to facilitate "first-in, first-out";

D. Inspect and evaluate the storage status of products from time to time, and complete the procedures in and out of storage;

E. The packing case should be stored in a dry and ventilated room or shed, and the bottom of the packing case should be raised when necessary.

3.4 handling

3.4.1 Mode of transport

By road transportation, other modes of transportation to be agreed by both parties.

3.4.2 Transportation Protection

A. Rain protection facilities shall be provided;

B. During transportation, the packing boxes should be placed according to the "up" mark, not flat or inclined;

C. During transportation, the length of the glass boxes should be in the same direction as that of the vehicle. The boxes should be close together, and measures should be taken to prevent tipping.

Instruction of assembly and construction method

4.1 Installation Method

1) In order to prevent damage during transportation, the produced products shall be packed in boxes, racks or in the form of packaging required by the customer and sent to the place agreed upon by both parties.

2) The installation process should be handled with care to prevent glass breakage.

3) During installation, installation personnel should use protective equipment to prevent glass from breaking and wounding.

4) When installing, use a soft rubber hammer to tap the installation part to prevent the glass from breaking.

5) Other matters not mentioned are subject to the agreement between the parties.

4.2 Precautions during Installation

1) The delivered products shall be checked and confirmed by the customer before installation.

2) When the packaging needs to be recycled, it needs to be properly preserved; Waste prevents pollution of the environment.

3) The delivered products should be stored in a clean, dry and ventilated warehouse before installation to prevent dampness, rain or heavy impact.

5 Precautions for Use

1) It is not recommended to clean the glass with cold water immediately after high temperature exposure to prevent glass breakage

2) In winter defrost, do not use hot water to clean the glass, to prevent the temperature difference ambassador glass broken

3) Clean the front windshield, try to use the specified window cleaner. Because the cleaning liquid added to dissolve oil, improve the glass wetting interface components, conducive to the maintenance of glass; When there is snow, ice, mud blocks, dry bird droppings and other obstacles on the glass, do not use the wiper, otherwise it will cause damage to the wiper blade, wiper motor and glass damage.

6. Scrap treatment of glass

1) The technical performance of automotive glass manufacturing secondary products is lower than that of primary products, so they are mainly used to manufacture all kinds of glass bottles or other glass products. Automotive glass in addition to the traditional glass, is now widely used in order to improve the strength of the sandwich glass. The so-called laminated glass is sandwiched between two layers of ordinary glass with a high molecular polymer layer to increase the safety of the glass. This glass recovery allows the laminated glass to be heated to the softening temperature of the intermediate polymer, thus separating the glass and polymer and recycling them separately.

2) If it cannot be recycled, please classify the waste glass and discard it in the trash bin in accordance with environmental protection requirements to avoid environmental pollution.

Weihai Yanhua Safety Glass Co.,Ltd.

provide customized service

Copyright © 2021 Weihai Yanhua Safety Glass Co,.Ltd All Rights Reserved

ICP 10027560-1

Technical Support:Weihai Leixun MANAGER